201964 Crane lifting wire ruptures

Edited from NTSB (USA) official accident brief DCA15LM026

A general cargo vessel was in port discharging wind turbine towers. Before starting work, the stevedore team discussed safe areas to be used during each lift. Two towers had already been discharged from the hold and the stevedores rigged the third tower for the lift. As the tower section was hoisted out of the cargo hold, a popping noise was heard.

Recognising this sound as a wire rope failing, the stevedore supervisor yelled ‘Hit the deck!’ Some stevedores had already started to exit their respective ‘safe areas’ at this point. The tower fell back into the hold and flying debris from the impact injured two of the five stevedores in the hold. The investigation found that the main lifting wire of the ship’s crane had failed even though it was used within its safe working limit (SWL). This wire showed signs of inadequate lubrication; lubricant was not distributed down into the inner wire surfaces.

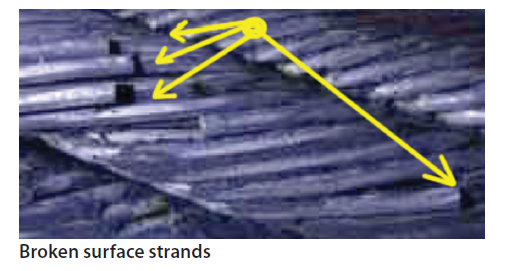

Evidence was also found of broken surface strands,(see image), which should have been apparent if visual inspections had

been effective.

Lessons learned

- The SWL of a crane means nothing if all the parts, and especially the wire rope, are not maintained and inspected to the highest standard.

- Lubricating the interior of wire ropes requires special tools and procedures. Lubricating only the exterior of the rope is an accident waiting to happen.

- Exacting procedures and communication are needed when coordinating cargo lifts while persons remain in the hold.