201034 Hazards from poorly maintained burning and welding equipment

Hazards from poorly maintained burning and welding equipment

MARS Report 201034

Edited from IMCA Safety Flash 09/09

|

|

|

|

|

On an offshore support vessel, sub-contractors were engaged in burning and welding sea fastenings on the main deck. After flames were observed at an acetylene tank regulator, operations were suspended and the fire was successfully extinguished. After cooling, the regulator was removed for inspection (see Figure 3) and it was found that thread sealing tape had been inappropriately used in all the connections on the contractor's equipment.

Further hazardous conditions with 'hot work' equipment on the same vessel were:

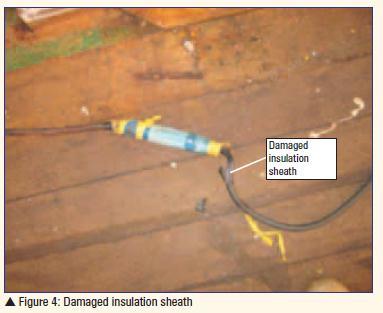

A welding cable was found to be smoldering at a connection point where the cable had been pinched and the insulation sheath was cut and the wires exposed (see Figure 4);

A midway cable connector was found arcing and smoking during deck welding operations (see Figure 5);

A nozzle head was found detached from an oxy-acetylene torch.

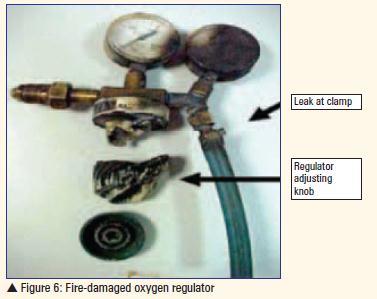

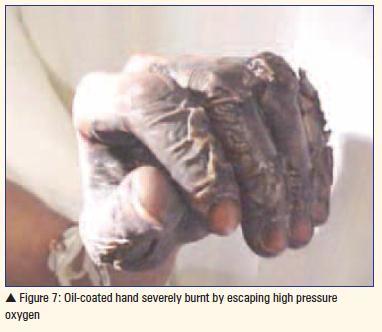

Whether belonging to the vessel or sub-contractors, poorly-maintained burning and welding equipment present a serious hazard to personnel and vessel. In a separate incident, a welder's hand was severely burned while he was adjusting the pressure, on an oxygen regulator. The welder had oil on his hand and there was an oxygen leak from the hose clamp. The oxygen stream under pressure instantly caused the hydrocarbons (oil and grease) on his hand to catch fire, the violence of which even blew away the regulator knob. Never allow oil or grease or any organic matter to come into contact with oxygen under pressure (see Figs 6 and 7).