Green shipping: the compliance challenge

Captain Sajith Babu AFNI is a member of The NI Younger Members’ Council and works as a Marine Operations Superintendent with a ship management company based in Singapore. In this article, he explores the issues and challenges around environmental compliance at sea and examines the knowledge and skills required to stay ahead

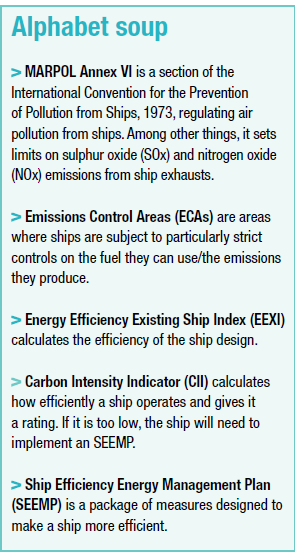

There is a general feeling that MARPOL Annex VI, which regulates emissions from ships, is the responsibility of the engineering officers, and there is nothing much that the navigating officer on watch needs to be aware of. However, this is an issue that everyone must take an interest in, and responsibility for, whatever their role on board. Ship Masters will be all too aware of the enormous number of emails between the ship managers/owners and the Classification societies aimed at getting the vessel fully compliant with the CII norms governing carbon carbon efficiency. Here, too, navigation and passage planning has a part to play. Let’s take a look four key areas that have been identified as contributing to a ship’s environmental impact. Each one needs to be monitored on a regular case-by-case basis by the navigating officers on board ship:

Ship speed optimisation

Vessels running at maximum rpm will burn considerably higher amounts of fuel than vessels running at a more economical speed. The consumption of fuel is not always proportionate to the increase in engine rpm. Ship owners and operators are urging vessels to run at economical speeds more than ever these days, in order to save fuel and (indirectly) achieve stated CII targets.

Weather routing

Weather routing has been something that must be checked prior to the start of a voyage for a very long time now. Previously it was just the Master and navigating officers who carried out this task. Today, however, most of the major ship operators employ third-party weather routing services to assist the vessel in avoiding heavy weather and helping its crew to plan economical and safe routes.

Just-in-time arrival

It is a common sight nowadays to see vessel owners and operators advising vessels to arrive just in time at the next destination. Most vessels are advised by their owners/ operators to economise and get there just one or two hours prior to the given cut-off time, rather than arriving earlier and waiting at anchor. This also cuts down on emissions while waiting.

Ballast optimisation

This is a relatively new approach and is currently being implemented and monitored by most ship owners. Updates to loadicator software include a ballast optimisation feature that calculates the most suitable condition for a vessel for the upcoming voyage, which leads to fuel savings, once again indirectly achieving compliance with CII norms.

Knowledge and skills

Navigating officers also play a major role during fuel changeovers prior to entering ECA areas. First, the senior engineering officers carry out fuel consumption calculations to determine exactly how much time is required for an effective change over. Following discussion with the bridge team, the optimal position for the start of changeover is decided. This is important, because even with the correct fuel on board, a mistimed or improperly executed changeover will result in violations within the ECA.

Re-skilling, upskilling

Navigating officers play just as much of a role in achieving environmental compliance, decarbonisation goals and greener shipping as engineering officers. Adapting to these new regulations also requires upskilling. Shipboard officers must be agile and innovative with a broader thought process to take advantage of the digital technology. As alternate fuels gain traction, shipboard officers will also need to gain knowledge about how they work and what advantages they offer, irrespective on the type of ship they are currently on. Crew working on board any vessel that uses methanol or ammonia as fuel will need to be aware of the specific hazards and safety protocols related to them. Shipboard officers will also need to understand how these fuels affect equipment operation and maintenance, and any potential limitations in their operation.

Changes and challenges

In recent years, people have become increasingly aware of the environmental impact of shipping. This is largely due to the steady enforcement of legal regulations, both locally and internationally. Strict enforcement of these regulations has also led to a reduction in the number of shipping incidents over the past decade. If the fuel does not meet low sulphur requirements, for example, port state or flag state authorities may require its debunkering and replacement and a deviation from the intended route, which can all cause delays and additional costs. MARPOL violations may also result in hefty fines against the vessel.

It is not surprising that seafarers sometimes feel penalised, even when they believe that they are doing their best in challenging circumstances. The fear of being punished or held liable for incidents in which other stakeholders, including bunker suppliers, are often partly to blame, can also be very real. Not only does this impact adversely on morale on board, but there are possible health and safety implications to consider when working out how to support seafarers in fulfilling the requirements.

Responsible ship managers and operators have developed standard procedures for ship staff to follow to ensure that international regulations are met, and to avoid the risk of being penalised or fined. Never overlook or ignore the safe working procedures and protocols – they are put in place for your protection.

The wider picture

It is evident that the maritime community, and society as a whole, is benefitting hugely from seafarers’ commitment to environmental compliance and the MARPOL regulations at sea. What’s next, then? Just as we have accepted, changed and trained ourselves in dealing with the ever-evolving MARPOL regulations ranging from Annex I to Annex V, now it is time to do the same for Annex V and beyond. The challenge goes on.