202406 : Bad hose blanking practice

Two tankers were carrying out a ship to ship (STS) transfer in port. The receiving vessel was moored at dolphins, with the supply vessel secured alongside.

Upon completion of the transfer operation, the cargo hose had to be drained to the receiving vessel before the vessels separated.

Under the instructions and supervision of the Person in Overall Advisory Control (POAC – appointed by the voyage charterers of the receiving vessel), the cargo hose was disconnected from the supply vessel. The POAC instructed the crew to put a rag in the flange of the cargo hose to create a small clearance and loosely bolt the blank in order to allow air into the hose to ‘facilitate’ draining to the receiving vessel when the line was raised. This arrangement was not communicated to the crew of the receiving vessel, so there was no opportunity for crew to challenge this practice or exercise their ‘stop work authority’.

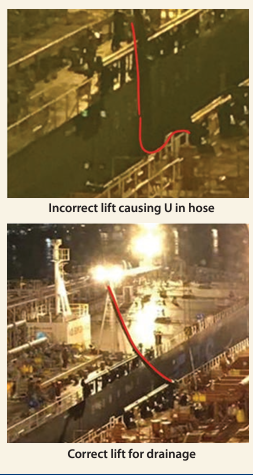

The first attempt to lift the cargo hose was unsuccessful. The hose was lifted only 10m over the upper deck, leaving another 14 metres of hose bent in a U shape between the vessels. Due to the improper lifting and U shape, the cargo line could not drain to the receiving vessel and an excessive bend developed at the hose support of the receiving vessel. This created so much pressure in the hose that the oil remaining in the hose was forced up and back out, escaping the hose at the loosely bolted flange at the supply vessel. An estimated 15L of oil was sprayed on deck, onto the fenders, and into the sea between the two vessels.

Lessons learned

- STS guidance specifies blanked flanges should be securely bolted to prevent pollution.

- Introducing atmospheric air to the cargo system constitutes an explosion risk.

- A STS Joint Plan of Operations should include all operations such as cargo hose connection, draining, purging and disconnection.