201978 Uncontrolled load swing injures crew

Crew were tasked with removing an air compressor motor from its enclosing cabinet. Because working space around and in front of the

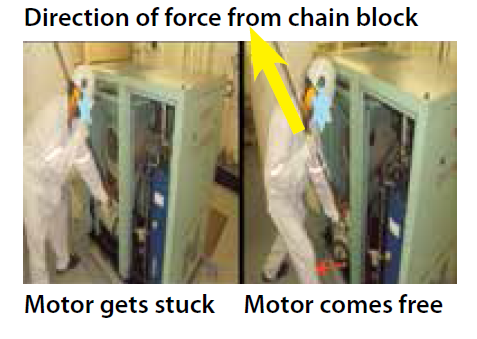

cabinet was restricted, chain blocks were installed to lifting eyes on either side of the compressor to facilitate removal of the motor.

While the motor was being lifted and slewed outwards from its foundation, it became stuck. A crew member attempted to clear it. As he was doing so, the motor released itself and swung out under the force of the hoisting chain block, striking his right shin.

The victim sustained an impact injury and was given first aid. The crew member had positioned himself on the axis of the motor swing while clearing it from the frame. He had not identified the risk associated with space limitation while handling the motor. The chain

block that was used to slew the motor was held slack, hence there was no control on the motor’s swing.

Lessons learned

- A lifting hoist should be placed at right angles when removing any heavy load. If this is impossible a slewing hoist must be kept taut.

- This incident illustrates the importance of a detailed risk assessment and discussion during the toolbox meeting before any job.

- Consider all potential hazards such as space restrictions, lifting eye position and total control of the object during the manoeuvre.