201849 Waxy deposits in low-sulphur MGOs

Waxy deposits in low-sulphur MGOs

MAIB Safety Bulletin SB1/2017 and Japan Transport Safety Board Report MA2017-12

A container vessel had been operating in the North Sea Sulphur Emission Control Area (SECA) for several days. The auxiliary boiler fuel supply had been switched from heavy fuel oil (HFO) to marine gas oil (MGO) to comply with emission regulations in the area. The boiler had cut out several times due to flame or ignition failures. On each occasion, the fault was investigated and the boiler reset by the second engineer.

The second engineer and the oiler were trying to restart the boiler burner unit when an explosion occurred. The force of the explosion blew the boiler burner unit door open and propelled the air diffuser into the engine room, killing the oiler who was standing directly in front of the burner unit. The second engineer was close by and sustained non-life-threatening injuries.

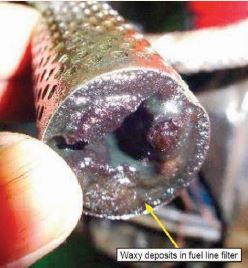

Examination of the boiler fuel system identified a build-up of waxy deposits in the supply filter, sufficient to restrict the fuel flow. Samples of the MGO being burnt at the time of the accident were sent to a laboratory for analysis. The tests found that the fuel had a cold filter plugging point (CFPP) of 14°C and a pour point (PP) of less than -9°C; it therefore required a minimum fuel operating temperature of 15°C. The ambient air temperature at the accident location was about 4°C, low enough for wax to form.

Safety Issue

Since the more stringent sulphur emissions limit was introduced, there has been an increased incidence of boiler and marine diesel engine problems in colder waters, industry reports suggest. This has been attributed to the increased paraffin content found in some low-sulphur MGOs, which leads to the formation of waxy deposits or crystals as the fuel temperature falls. Restricted fuel flow due to wax deposits in filters and pipework can cause intermittent and incomplete combustion to the point of flame failure. This could have unintended consequences, as in this case.

The paraffin content of MGOs varies globally due to disparate regional crude oil composition and refinery processes. Prior to March 2017, the often-used ISO 8217 standard focused on pour point. But this specification does not provide any indication of the temperature at which filtration issues may occur.

Lessons learned

When purchasing low-sulphur MGO bunkers, give careful consideration to the ambient air and sea temperatures likely to be experienced during the voyage. The required cold flow characteristics of the fuel being supplied using cloud point (CP) and CFPP must be appropriate.

If necessary, the CP and CFPP of the fuels carried on board can be tested through sample testing.

When operating in cold climates, the risk of waxy residue developing in the vessel’s fuel lines can be controlled by:

- Closely monitoring the visual appearance of low-sulphur MGO bunkers for signs of wax precipitation.

- Conducting regular fuel filter inspections and close monitoring of fuel system pressures.

- Maintaining the temperature of the low-sulphur MGO in the vessel’s tanks and pipework above the CP and CFPP temperatures to avoid the possibility of filter blocking.

The addition of cold-flow improver chemicals to the low-sulphur MGO in the vessel’s storage tanks should only be considered as a last resort, and then only under the strict guidance of an additive supplier.