201720 Thread mismatch causes misfire

A ship’s officer was tasked to recharge a compressed air bottle from the lifeboat. During charging, the union/adaptor connection between the compressor and the air bottle disconnected and blew away. Pressure in the bottle at the time was about 100 bar; the maximum designed pressure of the air bottle is 200 bar. Luckily, no-one was injured.

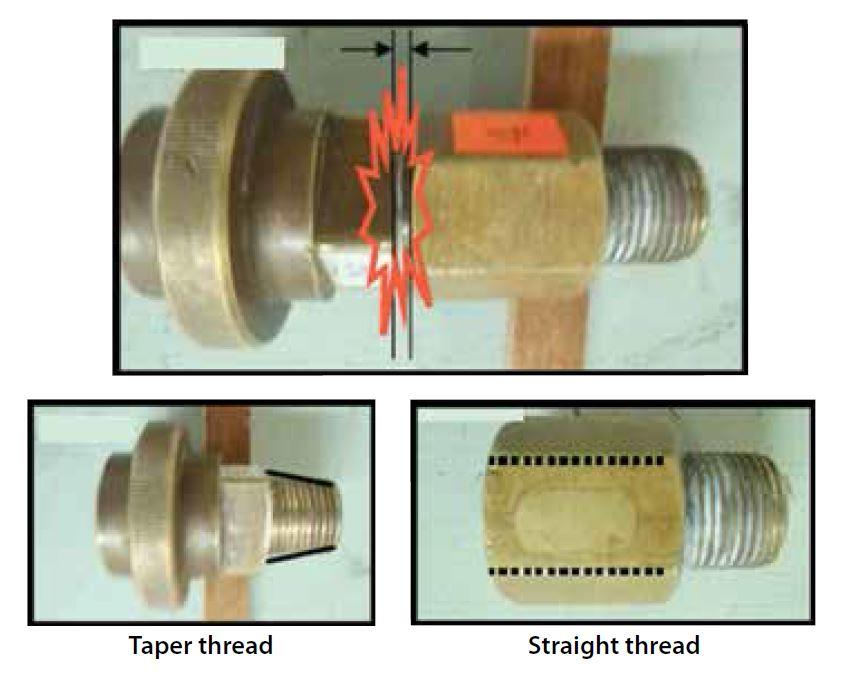

The company investigation found that the specification of the union/ adapter used on board was a different specification from the original. The male part of the union was a taper thread while the female part was a straight type. A proper fit would have matched fittings; taper with taper or straight with straight.

Lessons learned

- Air compressors create high pressures so accidents involving them can have serious consequences.

- Training and familiarity with the equipment is needed before use.

- Always inspect compressor fittings carefully before connecting; sometimes mismatched parts can be mistakenly used.