201665 Incinerator exhaust plugged

The incinerator was fired up by an engineer. When the temperature of the secondary chamber had reached 400°C, the primary burner was lit. About five minutes later, when the primary burner was at about 300°C, garbage was fed into the incinerator. After about one hour of operation the incinerator was stopped to allow a period of cooling down. About 20 minutes later, the incinerator was again fired up and fed garbage, although the primary burner was only at a temperature of about 250°C.

After about three minutes of operation the incinerator vacuum broke and smoke started to come out of the burner air inlets. Smoke continued to exit the burner blowers for another 10 minutes until the garbage inside the incinerator was completely burnt. In the meantime, the incinerator main blower had been tripped as a result of excessive back pressure. Although the fire alarm had been sounded, the water mist system did not activate because there was no flame. Once the smoke had cleared and the incinerator stopped an investigation was carried out.

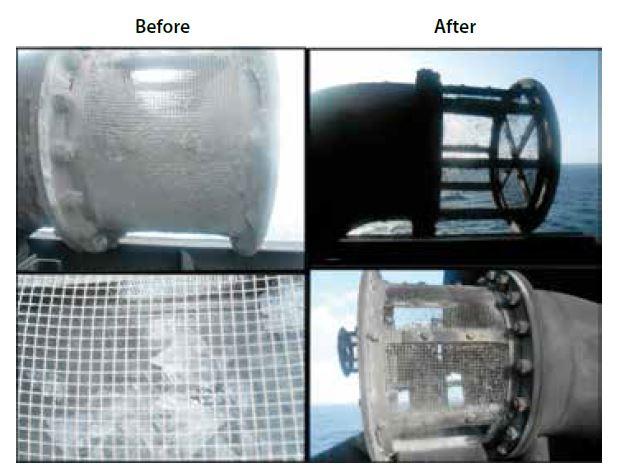

Among other things, the incinerator funnel flame screen was found to be completely clogged with unburnt paper and soot, which prevented proper exhaust flow (see photos below: before and after cleaning). Feeding garbage into the incinerator when the primary chamber temperature is below 600°C can result in unburnt light materials blocking the flame screen at the funnel.

Lessons learned

- Deviations from procedures can cause accidents. In this case, each deviation led further down the casualty path;

- Feeding material into the incinerator when the primary burner temperature is lower than 600°C can cause unburnt garbage to collect at the incinerator funnel flame screen.

- The funnel flame screen was allowed to become clogged, setting in motion the subsequent sequence of events.