201515 Safe haven not safe

Edited from the Marine Safety Forum – Safety Flash 14-34

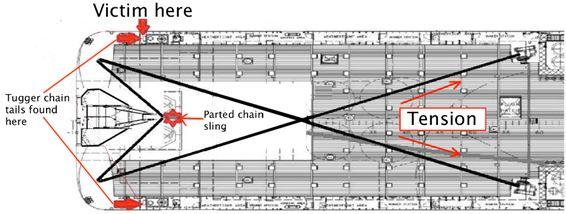

An anchor handling tug (AHTS) vessel was deploying a 15 ton anchor during a pre-lay operation. Deck personnel were using tugger wires with an endless chain sling connected through the anchor D-shackle to move the anchor along the deck and over the stern roller. During the operation, the rigging assembly (endless chain) parted and both tugger wires recoiled around the cargo barrier. Even though the deck crew were positioned in so-called safe havens, a crew member was struck on the head by a tugger wire and suffered a fractured skull and jaw as well as lacerations to the neck. The victim was provided with medical treatment on board the vessel and transferred to hospital for surgery.

Lessons learned

* Snapback zones were not adequately identified during the job planning.

* The safe haven for deck crew was not adequately assessed.

* Procedures did not incorporate calculation of expected loads, sizing/selection and use of rigging and its limitations.

* Small wire and loose rigging equipment failure has become ‘accepted practice’ on many AHTS vessels.

* Chain slings are not to be used in configurations such as in this accident due to reductions in Minimum Breaking Load (MBL) as a result of a non-linear pull and rigging around sharp edges. In these circumstances it is possible to have a reduction in MBL of up to 50%.

* When wires and equipment are under tension, no personnel should be located aft of a line extending between the most forward tugger winches on both sides of the cargo rail. The only exception being to take control of anchor handling safety systems such as check of shark jaws.

* The use of a higher grade of chain (120 for example), designed specifically for extreme conditions, should be investigated to improve the factor of safety during such operations.