201324 Improper footing caused ankle injury

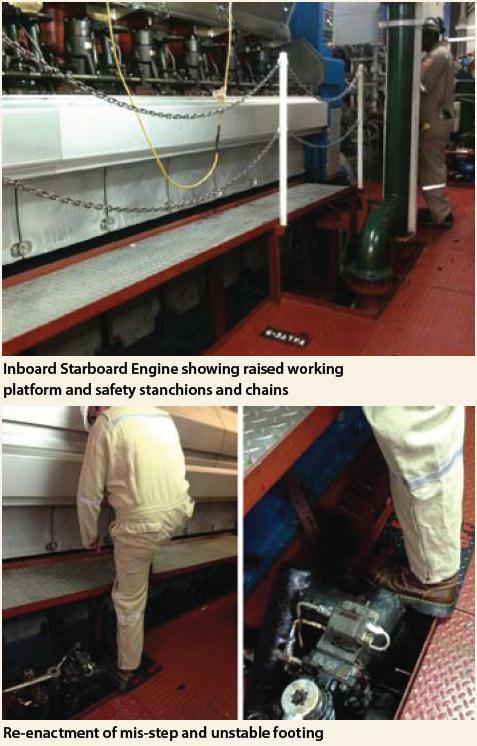

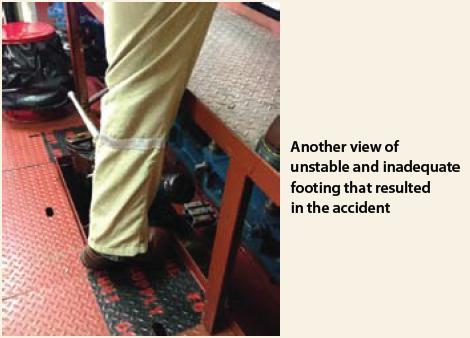

The engineering crew was engaged in maintaining the starboard main engine from an adjacent work platform. A Job Safety Analysis (JSA) had been completed for this particular maintenance work. To better access parts and tools required to complete the work, the safety chains and stanchions were removed from the perimeter of the raised work platform, running along the engine side about half a metre above the deck plating. As the work was nearing completion, the Assistant Engineer, while facing the engine, hastily stepped back from the work platform and down to retrieve a part from the floor plates. In doing so, he inadvertently placed his left foot on the vertical flange of the angle iron frames holding the chequered plates. With almost his entire body weight resting on the heel of his left boot , which was supported on the edge of the angle iron, his footing slipped and his ankle rolled inward resulting in torn ligaments and a Lost Time Incident (LTI).

Root cause/contributory factors

1 Inadequate work direction/preparation/JSA. The full implications of removing the safety chains and stanchions were not fully discussed / considered;

2 The JSA and risk assessment conducted did not adequately identify slips, trips and fall hazards.

Corrective/preventative actions

1 Engineering Supervisor and Master reviewed vessel-specific JSAs and identified areas which required further dissemination – including the removal of safety barriers;

2 A special safety meeting was held aboard the vessel to discuss the incident;

3 Operations Department distributed a Fleet Safety stand-down order, reviewing the circumstances and requesting feedback from the fleet;

4 Subsequent to this report, a more detailed account with root causes and lessons learned was distributed. This incident was also reviewed in detail during weekly fleet teleconferences.

Official report

1 A thorough risk assessment exercise meant to identify additional hazards related to safety barriers, particularly in the engine room, was commenced on all vessels;

2 Engineering Department is also reviewing platform design for modification, including steps or removable tool stations for periodic maintenance.

Lessons learned

1 When removing safety fittings / barriers, special precautions and documented processes must be implemented;

2 It is the responsibility of both the supervisor and the employee together to carefully review all latent risks in any operation – especially those involving control of work processes;

3 Individual situational awareness cannot be over emphasised. Crewmembers must be alert for hazardous conditions and feel encouraged to report the same to their supervisor;

4 All crewmembers in an organisation must be given the authority and responsibility to speak up and stop unsafe operations.

Feedback published in September 2013 issue of Seaways

I read with interest report number 201324, where an improper footing caused an ankle injury. There was no mention of the footwear worn for the task. Slip resistance of the soles of boots varies significantly, so it would be possible to wear boots that provide greater slip resistance. We use a human subject based ramp test derived from DIN51130 to test the slipperiness of footwear which provides a very good comparison of the slip resistance with bespoke combinations of surface and contaminant. There has also been some work done in the off-shore oil sector showing that use of laced ankle boots can reduce the severity of ankle injuries when a mis-step does occur.