201141 Crew fatality caused by parting of rescue boat wire fall

Edited from MAIB Safety Bulletins 1 and 2 2011

The crew of a large vehicle carrier was concluding a routine launching drill of the rescue boat in port. As the craft was coming up to its normal stowage position, a proximity sensor/limit or cut-off switch arrangement (Figure 1) that was designed to cut electrical power to the winch motor failed to operate correctly. With the davit having come up hard against its stops, the hoisting motor continued to wind in the fall wire, causing it to part. The rescue boat and its four crew fell nearly 29 metres into the water. One of the boat's crew died and two were hospitalised.

The parted fall wire was observed to be in good condition and when tested after the accident, it achieved a breaking load of 137kN. Although the winch motor was rated with a nominal pull of 50kN, the maximum pull that it was capable of exerting when trying to overcome the increased resistance in the system during the final stages of hoisting would have rapidly exceeded the breaking load of the wire.

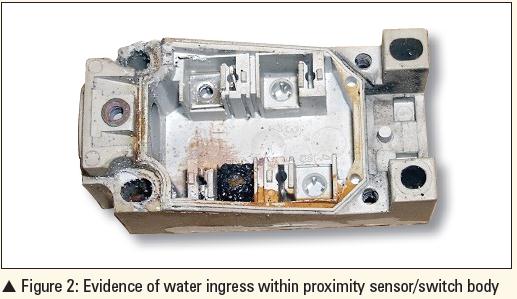

The proximity sensor/limit switch was tested in situ and was found to be defective. It had been installed in 2006, and during the ill-fated drill, was not tested before hoisting was commenced. Inspection revealed evidence of water ingress (Figure 2), although subsequent tests showed that the switch malfunctioned due to an unrelated electronic fault.

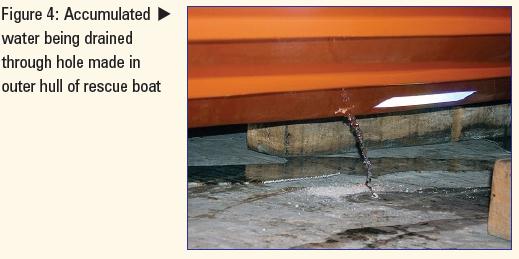

During the investigations, it was also unexpectedly discovered that water had entered the foam-filled buoyancy spaces between the inner and outer fibreglass skins of the rescue boat's hull (Figures 3 & 4). The craft was found to be approximately 450 kg overweight. Although the additional weight of water caused the davit's SWL to be exceeded, it was established that this would not have caused the wire to fail.

Lessons learnt

The maximum pull of a hoist winch can exceed its nominal pull several-fold, and therefore is likely to exceed the breaking loads of other system components unless this is prevented by a properly functioning 'final stop' or safety device;

The proximity sensor/limit switch fitted to the davit was considered by its manufacturer to be inappropriate for use as a 'final stop' or safety device. Operators of all vessels fitted with similar davits and safety devices must understand the potential limitations of the switches and take immediate and appropriate corrective actions;

The proximity switch was incorrectly fitted with its cable entry gland higher than the switch body thereby increasing the possibility of water ingress.

Corrective/preventative actions by davit makers

A notification was issued to customers advising them to:

Test all proximity switches on each occasion before hoisting operations commence;

Replace all proximity switches every two years;

Exercise caution when using pressure washers in the vicinity of these sensors/switches.

Main recommendations for ship operators

Ensure that all devices (inductive or mechanical) fitted to boat davit systems to prevent overload are tested on each occasion before a boat is hoisted and that sole reliance is not placed on such devices;

Follow manufacturers' recommendations regarding the maintenance and periodic testing, examination and replacement of safety devices, seeking clarification from manufacturers where ambiguity exists;

Verify the effectiveness of watertight seals on electrical equipment fitted to boat davit systems on weather decks.