201059 Problems with heavy lift cargoes

Problems with heavy lift cargoes

MARS Report 201059

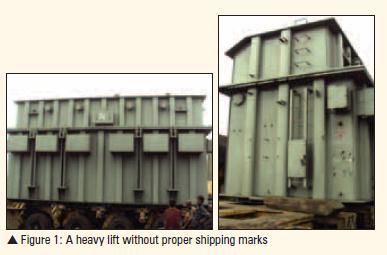

I am a port captain and among other jobs, I oversee the discharge of a large number of project cargo consignments. I have often noticed that the ship's staff has not planned the lifting and discharge process properly. Most worryingly, in some cases they were ignorant of the actual weights of the heavy lifts, and were intending to use the ship's gear without realising that the weight(s) exceeded the SWL. At the load port, shippers and ship's staff must ensure that crucial information like gross weight, slinging points, centre of gravity etc are prominently marked on each unit (preferably on each side and the top) and discharging arrangements at the destination port are clearly understood between all the parties involved.

Some receivers put pressure on the vessel to handle heavy lifts during the night; in my opinion, this must be resisted and charter-party clauses worded so to ensure that such work is to be conducted only during daylight and in 'safe' weather conditions.

One must appreciate that the consequences of an accident when handling heavy lifts can be very serious. Apart from the obvious danger to life and limb, there is the certainty of severe damage to cargo, vessel, lifting gear, berth and shore installations, resulting in long down times and huge claims.

Editor's note: As an example of best industry practice, a condensed extract from North of England P&I Club's Signals Newsletter Issue No 76 is reproduced as a MARS report (201060). Further information can be obtained from Nepia Signals 76 and Nepia's loss prevention guide, Cargo Stowage and Securing – A guide to good practice.