200959 Laundry fire

Shortly after a messman had placed some bed sheets into the ship's tumble drier, an alarm for main switchboard low insulation was activated. At the same time, the messman noted smoke originating from the tumble drier.

Shortly after a messman had placed some bed sheets into the ship's tumble drier, an alarm for main switchboard low insulation was activated. At the same time, the messman noted smoke originating from the tumble drier.

What happened

Investigation by the ship's staff determined that an increase in the operating temperature of the heater element, caused by lack of air circulation, led to ignition of the surrounding cabling and gasket material. On observing smoke, the messman removed the bed sheets but could not identify the location of the fire. A passing duty AB on fire patrol informed the OOW of the situation, which was further investigated by off-duty second officer before the alarm was raised and personnel mustered. Shortly afterwards, the fire detector head in the passageway was activated.

What went wrong

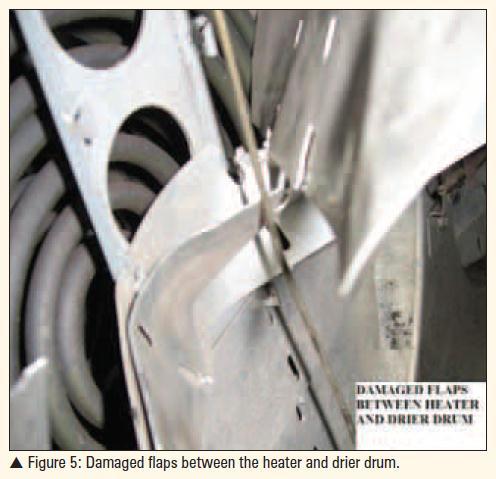

Close examination identified that a previously undetected failure of the 'jalousie' mechanical vents resulted in poor air flow and increase in operating temperature of the element.

On detecting the fire, the laundry was not evacuated and door was not closed. This allowed smoke from the fire to enter the passageway.

The manufacturer's instructions in respect of inspection and servicing the equipment was lacking in the detail that might have prevented this type of incident.

Root cause analysis

Lack of standards: Although in the company's planned maintenance procedure, washing machines, tumble and spin driers, irons and small electrical items are subject to a three-monthly general check/inspection, it was accepted that this was insufficiently detailed to identify the jalousie vent arrangement or its importance to the continued safe operation of the equipment.