200958 Inefficient door fittings and joinery

On too many ships, I have noticed that hydraulic door closers are defective, improperly mounted or adjusted and sometimes, in very crucial doorways, missing altogether.

- Defects: Oil has leaked out of the cylinder, causing no delaying action and the door slams instantly with great force, especially if assisted by circulating air. In many instances, repeated violent motion has torn away the actuating lever, putting the equipment beyond repair.

- Improperly mounted: Most doorway frames are of pre-fabricated, powder-coated mild steel sheet, typically 2-3 mm thick. The door closer cylinder unit is mounted on the door shutter and made of similar material or, for, non-class A doors, may even be laminated 'particle board'. Fasteners are usually self-tapping or machine screws with very minimal grip. Not surprisingly, things start to come apart a few months after leaving the shipyard. To compound the problems of poor joinery, the countersunk machine screws holding the hinges have a tendency to slip or loosen and drop off. Finally all this 'work and play' puts a wobble in the highly-stressed anchoring point of the hydraulic closer's actuating lever, the screw hole expands and the screws get dislodged and the closer's components begin to droop and acts as an obstruction, preventing the door from closing at all.

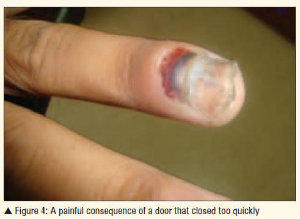

- Poorly adjusted: Most sensible manufacturers provide some means to control the initial swing and the final closing rates. These must be adjusted optimally to give a smooth and controlled speed of closing, and fail-proof latch activation. A door that shuts with the speed of a falling guillotine poses an unacceptable safety hazard to persons.

- Missing: Often due to frustration, the ship's crew removes the ill-fitting and malfunctioning door closer and even more hazardous arrangements are improvised like tie-back ropes, hooks, wooden wedges, and packaged items from the stores.

On a different subject, interestingly, on the vessel on which I am currently serving, built for unlimited world-wide trading, all drawers are provided with super-smooth ball-bearing mounted rails but no thought has been given to fitting a spring catch or stopper arrangement to secure them at sea. Consequently, as soon as the ship leaves the wharf, all the drawers slide in and out, like so many ghost cash registers. Considering the number of times one's rest is disturbed in order to stuff another wad of paper to hold a rogue drawer shut, I wonder whether this might constitute a violation of ILO 2006 crew accommodation standards.

Suggestions for improvement:

- Shipowners, shipyards, classification societies and P&I clubs must jointly ensure that doors, drawers and associated fittings are robust and suited to the marine environment in which they are to be used.

- Automatic door closers must be fitted on all doorways meant for public access and through which persons are likely to carry objects.

- Doorway frames and shutters should be made of thicker gauge and door closers should be fixed using rivets or through bolts with backing plates and self-locking nuts.

- The proper fitting and operation of door closers must be included in every safety audit.