200520 Dangers of Container Operations

Dangers of Container Operations

MARS Report 200520

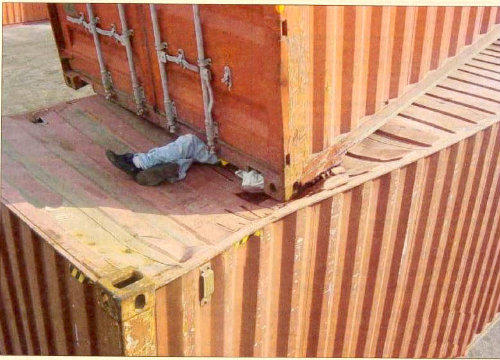

I read with Interest MARS report 200442 which showed a fatality during container operations. (photograph 1).

|

PHOTO 1 |

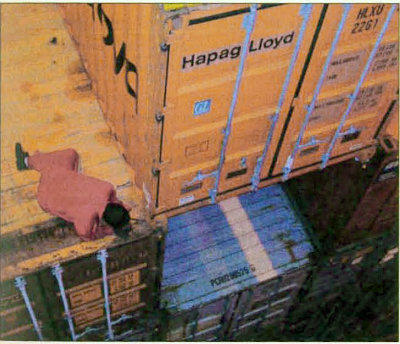

PHOTO 2 |

Photograph 2 shows a situation which happened on a vessel which was under my command. The only difference is that the officer lying down is still alive. When I saw what he was doing I nearly had a heart attack and I still have nightmares about what might have happened to him.

In spite of all positive regulations concerning safety in cargo operations, Code of Safety Practice, ISM Code, common sense, and more, such accidents are still a reality. I have spent almost all my career on container ships and I have gained a lot of experience. I have also seen many accidents caused by containers. All of them are the result of deficient safety measures.

The most dangerous place of the World is at the so called "Midstream Operations" at Hong Kong, China. Loading and unloading containers at Hong Kong, China anchorage is an extremely dangerous operation which requires additional safety measures and good pre-arrival preparation. I have seen broken legs, smashed arms, smashed palms, injured skull, etc. I have had to give First Aid to all of these types of accidents.

Shortly before my promotion to Master, as I was walking on the main deck, I was hit by "flying" twistlock from a hatch cover. Luckily, a red safety helmet saved my life (see also MARS 200521 RB). The only consequence of this accident was losing consciousness for a few moments, vomiting for a few days and delay in promotion on my next contract.

In an Indian container terminal, the only type of protective clothing for the poor stevedores are cheap, thin shoes. Can you imagine the pain when a turnbuckle or lashing bar falls on such unprotected feet? Is the Master able to suspend cargo operations? The answer is yes, he is. However, if he did that, there would be no cargo operations at all and it would not result in the poor stevedores being provided with proper safety equipment and clothes.

We have a new generation of lashing equipment, especially the locks which have reduced the number of stevedores or crew needed around overhead hanging containers. However, in many ports, container operations are still carried out with ship's cranes. That is an extra difficulty for the Masters and crew. Crew and stevedores are still getting injured or killed, mainly due to lack of safety. I was arrested when part of the lashing equipment fell and injured a stevedore. The Duty Officer did not warn the stevedore that he had to wait before starting to lash until an overhead container was stowed. This was my last experience in America with an experienced stevedoring company and at a respected container terminal. Unfortunately, this will not be the last incident at all. However, let us try to work together to do our best in order to reduce number of accidents as much as possible.

Hong Kong, China's Marine Department has issued a reminder urging the observation of safe Practices in Container Handling.

In its Notice No.21 of 2005, dated February 16, 2005, the Marine Department states that on a rainy day in August 2004, a stevedore was found with a fatal head injury on a container top on board a dumb steel lighter. The container top was wet and no safety helmet or portable ladder were found at the scene. None of the stevedores saw how he was injured but it is most likely that he fell from the top of the next tier container, slipped on landing and hit his head against a sharp corner fitting.

To avoid similar accidents, owners, masters and operators of container carriers, stevedore companies, owners and masters and agents of Mainland coastal and river vessels and persons in charge of works are reminded to observe the following safety measures:

- the person in charge of works should ensure that all workers under his supervision use portable ladders to safely access container tops of the next tier, and ensure observance of safe practices as advised in 5.3.13 of the "Safety Guide for Shipboard Container Handling" published by the Marine Department;

- the principal contractor should ensure that subcontractors follow the above and implement a work control system to provide for personal protective equipment, in particular, safety helmet and slip resistant protective footwear to be worn by all stevedores during works.