Free Article : Maximising situational awareness in pilotage

Increasing accuracy and safety in all conditions by the use of PPUs

Cdr Paul Stanley FNI

Incidents during night pilotage

Some incidents which have involved loss of situational awareness at night are very well-known, such as:

CMA CGM Vasco de Gama, a 399 metre container ship, which grounded while turning into Southampton water at night. There were two pilots on board, with a high quality PPU and two good ECDIS displays, but none of the displays showed a suitable planned track for the turn in the prevailing conditions, making it very difficult to effectively monitor the turn. Having just passed an outbound ship, she was too far north when she started her turn to starboard, turning out of wind with limited under-keel clearance; consequently the rate of turn (ROT) reduced, and she grounded on the west side of the Thorn Channel. (UK MAIB report 23/2017)

Less well-known examples include two from Australia/New Zealand:

Leda Maersk, a 266 metre container ship, grounded after turning too sharply while negotiating a bend in the Otago Harbour at night. The ship was being navigated visually; a cross-track alarm from the ship’s ECDIS was not notified to the Master and pilot; the pilot had a PPU but he was not trained in its use and it was not properly set up so he chose to ignore it. (NZ TAIC report MO-2018-203)

Aquadiva, a 292 metre bulk carrier, was leaving Newcastle fully loaded at night with four tugs. As she approached the Horse Shoe

Turn (about 90°,) port rudder was applied but too little, too late. The pilot, concentrating on the ROT indicator, belatedly recognised that the ship was much further south than intended. With the aid of multiple tugs, the drift to the south was arrested with the ship well outside the fairway and possibly touching the bottom. The pilot had elected not to take a PPU with him on this job, despite the size of the ship, and was navigating primarily by visual means. (ATSB330-MO-2017-002)

Common features identified in the investigation reports for all these incidents include:

- Lack of a shared passage plan/mental model;

- Failure to use available electronic aids effectively;

- Failures of Bridge Resource Management (BRM).

Ravi Nijjer, of Marine Consultancy Group Australia, a major advocate and trainer for BRM, commented in relation to these and other pilotage incidents: ‘Evidence indicates that most of them show over reliance on visual navigation, local knowledge and pilot’s intuition, and that a PPU wasn’t used even though one was available’. The examples quoted above were deliberately chosen because they happened at night. As John Clarke noted, commercial airline pilots require instrument ratings for flying at night, but night pilotage is rarely treated as a special case. Even the largest ships’ arrival and departure times are often determined only by the tidal window available.

How can pilots manage the hazards?

Electronic pilotage techniques are a major aid to night pilotage. To be effective, though, the plan shown on the ship’s ECDIS and ARPA must be the same as the pilot is working to – which means the pilot’s plan needs to be communicated to the ship well in advance of the arrival/ departure: providing the plan during the Master/Pilot Exchange (MPX) is far too late! This is also true, of course, for daylight passages. Unfortunately, even with a common plan and a shared mental model, it is all too common for the pilot to receive very limited support from the rest of the bridge team. Consequently pilots become potentially a single point of failure and need to maximise their own ability to monitor the passage by alternative means. One of the most effective ways of doing this is to use a PPU.

PPUs

Most portable electronic aids for pilotage, whatever their overall level of sophistication, are referred to as PPUs, but for the purposes of this article only high-level units with independent position, and at least semi-independent heading and ROT, will be considered. So-called ‘PPUs’ which derive own ship position from the Pilot Plug – that is, using data received and transmitted from the vessel’s own AIS – are specifically excluded. The International Maritime Pilots Association (IMPA) cautions strongly against using them, not least because data derived from the pilot plug is not independent and will, at best, merely duplicate any errors from the ship’s sensors (for more details, see http:// www.impahq.org/admin/resources/guidelines.pdf).

For pilotage, one of the most valuable inputs into an electronic charting system is accurate ROT, with software that is able to use it in conjunction with position, and course/speed over the ground to predict future positions when turning. High-level PPUs all have this ability, whereas not all ECDIS systems do (and some older ships’ gyros do not even generate ROT anyway). In each of the groundings above, a PPU would have given early indication that all was not well; in the cases of CMA CGM Vasco de Gama and Leda Maersk, they did just that, but it seems no one was paying attention to them.

For comparison with the CMA CGM Vasco de Gama incident report, Figure 1 above is a screen shot from a recording made by the author during a PPU demonstration in 2006. It shows a 347 metre container ship rounding the Brambles Bank into Thorn Channel in the Solent (the track shown was not in use at the time of the recording, but was added later to illustrate the point.) The display shows the midpoint of the ship is eight metres to starboard of track, and predicts that if nothing changes she will complete the turn in about three minutes, safely but slightly to port of track, so the pilot should increase the ROT if possible.

Familiarity breeds – competence

PPU use on every ship is becoming the norm in many ports. When using a PPU, its operation needs to be second nature: it is dangerous for the pilot to be fiddling around with the equipment at critical junctures. After initial training, using the PPU on a regular basis – on every trip – builds the necessary familiarity and competence. Using the PPU on every trip also serves to build the pilot’s confidence in the performance of the equipment, knowing its reliability and accuracy. Having the PPU at the conning position gives the pilot instant access to accurate heading and speed without having to ask, and shows present and future positions on the chart without having to leave the preferred position. Subsequently, PPUs give pilots the potential to review individual jobs while they are fresh in the memory, which is invaluable in terms of improving performance. Indeed, the Cambridge Handbook of Expertise and Expert Performance concludes that superior performance comes from deliberate practice and regularly obtaining accurate feedback. The PPU provides that accurate feedback.

Precedence of PPU information

When the PPU is used for every pilotage, it becomes the one constant factor which doesn’t vary from ship to ship. It is the same familiar equipment, operating in the same way:

- By day or night;

- Whatever the visibility;

- Regardless of whether there is good support from the bridge team or the pilot is operating almost as a ‘one-man band’. A good PPU compensates very effectively for the deficiencies that can be found with bridge teams and can provide the pilot with a very reliable, and potentially invaluable, second opinion when it is most needed.

In some ports, particularly those handling large, unwieldy bulkcarriers with critical under-keel clearance requirements, the PPU has already become the main reference for pilotage. As with every other aspect of navigation it must not become the sole source, but must be used with whatever other information is available – be that visual, ECDIS or radar.

Other benefits from PPU use

It is worth noting that there are a number of situations where the PPU is able to provide really useful information that is not readily available by other means:

- Applying the height of tide (HOT) to the charted depths makes its display of navigable water far more useful than the ECDIS display. See Figure 1, where the HOT of 3.4 m has been applied. This is particularly so if operating with a bathy ENC (bENC) which will show far more depth information than a normal ENC’s standard depth contours/declared dredged depths.

- Combining the HOT with Dynamic Under-keel Clearance (DUKC®) information via a mask overlay can show the safe navigable water available as speed (and therefore squat) changes.

- It is especially effective for monitoring the ship’s performance when undertaking a constant-radius turn – and much easier than monitoring it on radar when otherwise conducting visual pilotage. See Figure 1 again.

It can display the cross-track distance (XTD) of the centre of the ship in relation to the planned track – which is much more relevant than knowing the XTD of the bridge. Although the displayed value will be different from measurements based on a Consistent Common Reference Point (CCRP) based on the conning position, the bridge on most ships is right aft and will invariably be well off track when negotiating a tight turn or coping with a strong cross-wind or current. Note that MSC 191/A allows alternative locations to be used instead of the CCRP as necessary, where clearly indicated or distinctively obvious (as is clearly the case with the PPU).

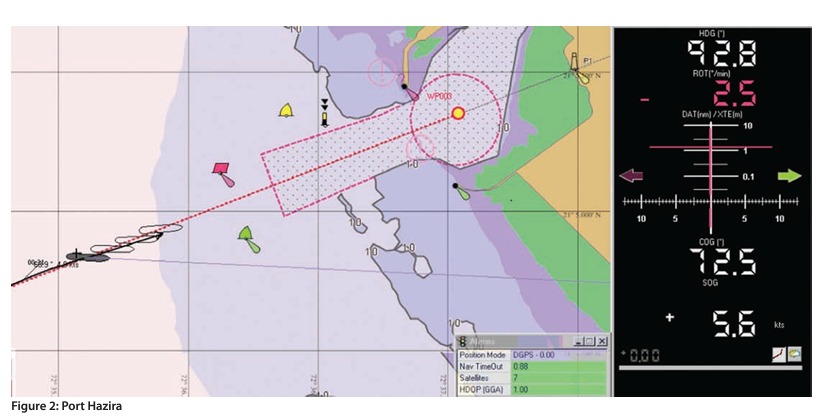

This is illustrated in Figure 2, where an LNG carrier is entering Port Hazira in India at low speed with a 2 kt cross-current. Although the centre of the vessel is on track, the whole of the bridge – and therefore the CCRP – is to port of the leads.

Efficiency gains from use of PPUs

There are many ways in which PPUs can improve port efficiency; though of course avoiding major navigational incidents is a major contributor to efficiency anyway!

PPUs can help considerably in removing some of the constraints which might otherwise limit shipping operations:

In Townsville, Queensland, they were able to resume ship movements very rapidly after Cyclone Yazi struck in 2011, despite having lost many of their navigational markers.

- In Ravenna, Italy, they can safely move ships in fog – which is prevalent in winter.

- In Port Hedland, Western Australia, they use their PPUs in conjunction with DUKC® mask overlays and bathy ENCs to regularly ship over one million tonnes of iron ore on a single tide, making it the largest bulk export port in the world.

- In Vancouver, they are able to take larger tankers through the very restricted Second Narrows, so reducing the number of oil shipments needed each year.

- In the St Lawrence River and on the Canadian Great Lakes they are able to move larger vessels into the ports of Quebec and Montreal, and extend the navigation season further into winter, as safe night pilotage is possible even when the lit buoys have been removed due to ice.

There are countless other ports which have also benefitted. In every case, though, it is because they have accepted that new technology enables them to expand their operating envelope. To do this they have to overcome the mind-set which says ‘you should never do anything with a PPU that you cannot do without it’. Additionally, PPUs provide a very valuable aid for training new pilots, who can be debriefed immediately after completing a job using the playback as a reference.

Choice of principal navigation reference

At risk of whistling up a storm, I suggest that the best way to achieve safe and efficient pilotage is to minimise the variables from job to job by always using the same prime source of information – a PPU. If that is a bridge too far, which I’m sure it will be initially for many pilots, at least make the PPU your prime secondary sensor – and in all cases provide redundancy by having exactly the same plan show on the ECDIS/ARPA.

It is important, though, that pilots’ skills in other forms of pilotage do not atrophy due to over-reliance on a PPU. Visual pilotage and radar blind pilotage need to be practised regularly, but with the PPU acting as a back-up and providing a record of what was achieved for subsequent playback and analysis. Indeed, the best pilotage will undoubtedly be achieved by using two methods in tandem and verifying one against the other regularly, scanning systematically between them.

Need for proper training and for regular QA

Even the best equipment in the world is of limited value if those using it cannot operate it properly. Ship’s bridge teams should be competent in operating their own equipment, though sadly that is often not the case. Pilots will be the sole operators of their PPUs and it is essential that they have proper training both in the general principles of PPUs and in the specifics of their own equipment. The IMPA guidelines for PPUs include a section on the factors to be considered for PPU training. Similarly, no equipment can be 100% reliable. Pilot companies need to carry out periodic checks of the performance of their equipment, and the manufacturers are best placed to advise on how that should be achieved.