202532 Crane test revels installation mistake

Providing learning through confidential reports – an international co-operative scheme for improving safety

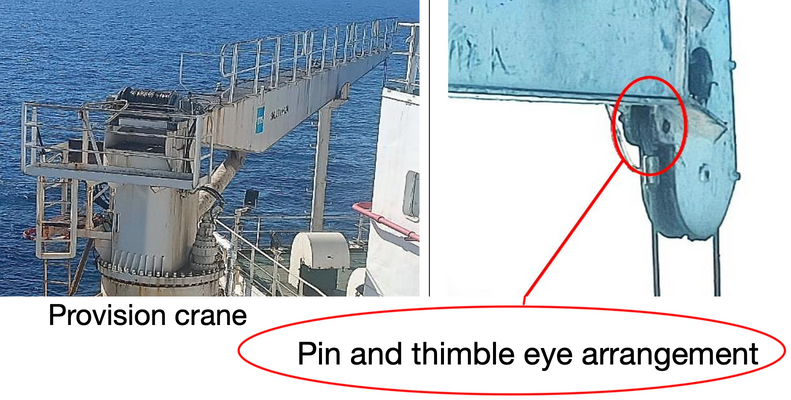

A cargo vessel was undergoing maintenance in a shipyard. Work on the provision crane was in progress and staging had been rigged to give access to the crane’s hydraulic ram, which was dismantled for overhauling. While maintenance work was still in progress on the hydraulic ram, ship’s crew were assigned to change the crane’s hoisting wire.

There was no staging rigged at this location. In order to connect the thimble end of the new wire to the securing point at the head of the crane boom, a crew member lay on his stomach over the crane boom and inserted the locking pin through the thimble eye with his outstretched hands. Essentially working by feel alone, the crew member inadvertently and unknowingly put the pin back in place without passing it through the thimble. The thimble remained in place, stuck between the boom structure and the locking pin.

Three days later, the hydraulic ram had been fitted, and the provision crane was load tested. A water bag of the required weight was lifted and swung outboard. As the load came on the wire, the thimble eye of the hoisting wire came out of its stuck position. The crane’s block, water bag and dynamometer fell in the water. They were later retrieved by shipyard staff.

Lessons learned

- After any safety significant work by crew, a senior officer should undertake a close-up inspection of the finished task for quality assurance.

- Proper access to the workspace is a must. Never ‘work blind’.