202124 Enclosed space: Deadly H2S goes undetected and rescue attempts are haphazard

As edited from the AIBN (Norway) report Marine 2020/02

A factory trawler was underway and being made ready for fishing. Crew had finished cleaning the factory and were preparing the silage tanks for cleaning. Silage tanks are special compartments that contain unused fish parts that are processed into silage and later pumped ashore (used to make oil and protein concentrate used in feed for farmed fish).

The tanks had last been cleaned about five weeks earlier and there was still silage residue at the bottom of the tanks. Cleaning these tanks included preparatory work such as flushing the tanks by filling them with seawater and emptying them several times and then lowering a fan into the tank to ventilate. The usual method was to lower the fan into the tank using a rope.

Access to silage tank

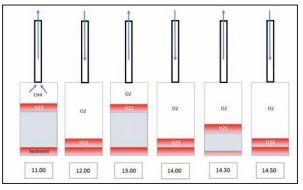

Flushing was accomplished as per the below diagram (not to scale). For the ventilation, a plastic hose was attached to the blower to channel the gases out into the open air. It had previously been a challenge to prevent the hose getting twisted when the fan was lowered, and it was decided to send someone into the hold to position the fan correctly, if safe. The oxygen level in the tank was measured by lowering an oxygen detector on a string, but it is not known how far down the tank it was lowered. The oxygen detector did not sound an alarm, and therefore it was deemed safe to enter the tank.

Two crew rigged the fan and hose. When the equipment was ready, one crew member with an oxygen detector entered the tank. After descending part of the way the fisherman shouted to his colleague on deck that there was a lot of silage residue left in the tank; he then proceeded down to the bottom of the tank. Suddenly, he shouted ‘There is no air here’ before jumping back onto the ladder. After a few steps he abruptly fell backwards, landing at the bottom of the tank, unmoving and face-down in the silage residue. The crew member outside the tank raised the alarm and one of the vessel’s Breathing Apparatus (BA) sets was brought to the access hatch.

Within minutes, the BA was donned and a crew member descended into the silage tank. He shouted up to throw down the end of a fire hose that he planned to use to hoist the victim up. Another crew member wearing a BA entered the tank, and the two of them attempted to fasten the hose around the victim, with limited success.

By the time the vessel’s lifting equipment was lowered into the tank, the first crew’s air ran out and he had to exit. Another crew member wearing a BA entered the tank and, together with the remaining rescuer, tried to secure the strop around the victim. They found the task very challenging as the victim repeatedly slipped out of the strop because he was unconscious.

Finally, as they were hoisting the victim up, his inert body was caught repeatedly on the ladder cage. Another 20 minutes passed before they finally managed to get the injured person out of the tank. When the victim was finally retrieved from the tank, CPR was immediately performed and attempts were made to resuscitate him using a defibrillator. This work continued non-stop, with most of the crew involved, until medical personnel from the local Coast Guard arrived. The medical personnel ascertained that the injured person had died and CPR was discontinued.

The investigation found, among others, that:

- The gas detector in use measured only the level of oxygen present. It was therefore not possible to determine whether the atmosphere was safe from other deadly gases such as hydrogen sulphide (H2 S) which is produced by bacterial decomposition of organic compounds containing sulphur such as, for example, the fish and fish waste in the silage tanks.

- The fisherman was probably exposed to a fatal dose (one or two breaths) of toxic hydrogen sulphide gas as he climbed down to the bottom of the tank.

- Efforts to rescue the victim from the tank were stymied by the lack of suitable equipment and training.

Lessons learned

- Enclosed space rescue is a specialised endeavour that requires specific equipment, training, and practice. Improvised rescue attempts put the victim and the rescuers at risk. SOLAS requires that crew members with enclosed space entry or rescue responsibilities participate in an enclosed space entry and rescue drill at least once every two months.

- Practising enclosed space rescue without the proper training and equipment is, at the minimum, an exercise in futility. At worst, this could engrain unsafe practices, putting the rescuers at risk.

- A best practice would have at least one crew member on the vessel who has attended a specialised enclosed space rescue training course. That crew member could act as enclosed space rescue team leader as well as on-board trainer.

- SOLAS requires testing enclosed spaces with a multi-gas detector which includes H2 S prior to entry. Testing for O2 content alone is not enough to allow safe entry into many confined spaces.

- For deep tanks, tests should be made and recorded for several levels including at the bottom.

- Another best practice is to have BA equipment ready for use at the enclosed space entrance before anyone enters that space.

- Finally, best practice would see anyone and everyone who enters an enclosed space first fit a safety harness with evacuation rings. This greatly facilitates any rescue should they be injured or incapacitated while in the confined space.

- All enclosed spaces should have a lifting lug positioned above the entry point or have the space available around the entry for a rescue tripod to be rigged.

- When the opening to a confined space is limited and/or the person being rescued is bulky such that passage through the exit space or up the ladder is hindered, the arms of the victim must be kept above their head as they are being winched up, either by the person themselves or, if the victim is unconscious, by the rescuers using a second line and a wrist strop.

- Although ventilation is more efficient using a positive pressure approach (fan pushing fresh air into the compartment), when circumstances dictate, a negative pressure approach can be used by extracting contaminated gases from the space.