202101 Lifeboat close call

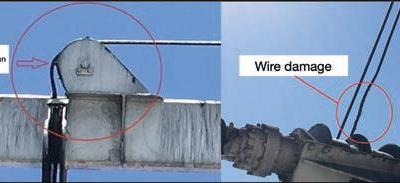

The vessel was at anchorage and a lifeboat drill was scheduled. The boat was lowered to the water and completed manoeuvres, the boat crew exited the lifeboat and recovery commenced. As the lifeboat was raised an officer noticed damage to the davit wire near the port side upper sheave.

The operation was immediately stopped and the condition of the damaged wire was investigated. It was found unsafe to use under load so a port crew boat was called. The lifeboat was lowered back to the water and brought to a berth while investigation and repairs were undertaken.

The investigation found that the davit’s wire had been incorrectly fitted to the davit sheave. It had been fitted on the outside of the sheave protection bar instead of between the protection bar and the sheave. This defective rigging had caused the wire rope to rub against the bar, which resulted in damage.

The lifeboat davit wire ropes had been installed two months earlier in dry dock. The defect had gone undetected during the load-test after installation and the boat had not been lowered since the test.

Lessons Learned

- As lifeboats are raised or lowered it is always prudent to sight the wires and check for defects.

- During dry dock maintenance many projects are often in progress simultaneously and at a rapid pace. In many cases, jobs are undertaken by shipyard crews who have less experience than vessel crews. These factors increase risks, so extra prudence is needed on board in the weeks and months after a dry dock.

- To minimise risks during drills, lifeboats should be raised without crew whenever possible.