201959 Anchor falls to bottom of dry dock

As edited from Marine Safety Forum Safety Alert 18-25

While in dry dock, the vessel’s anchors were ranged on the dock bottom for inspection and painting. Once the work was complete

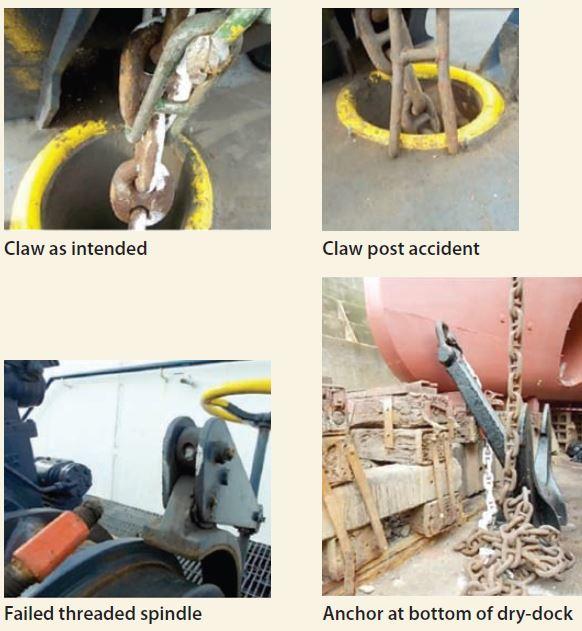

and the vessel due to depart the dock, both anchors were recovered. The brakes were applied, guillotines dropped across the links, and devil’s claws engaged.

After disengaging the clutch, the brake on the port anchor was given another turn to ensure tightness. The threaded spindle failed and the brake friction band instantly released. At that point, the full weight of the anchor fell on the devils’ claw and dropped guillotine. The weight of the anchor forced the arms of the claw open. Although the guillotine had been dropped across the cable,

it was not yet secured in place, and did not effectively stop the anchor cable running out when the claw failed. The chain and anchor ran out, unrestricted, to the dock bottom. Luckily no personnel were in the vicinity of the dropped anchor. The investigation found, among other things, that;

- Both linkages housing the failed threaded spindle were seized. The lack of free rotation in the linkages caused a torque to be applied to the spindle when the brake was tightened. Over time this caused metal fatigue within the spindle until complete failure.

- All parts of the windlass were greased regularly. However, as has been identified in other mechanical failures, grease from the greasing nipples had not penetrated every part of the equipment. This has led to the linkages becoming less than adequately lubricated.

Lessons learned

- When lifting or lowering anchors in dry dock, ensure personnel are clear of the area below the anchor at all times.

- Ensure grease points are effective in delivering lubrication.