202405 - Don’t be terminated by a faulty termination

A vessel suffered extensive damage to equipment when a wire rope swaged splice termination failed.

As edited from USCG Safety Alert 04-21

https://tinyurl.com/3an649am

The investigation reiterated the importance of verifying the condition and appropriateness of wire rope terminations used in a load-handling capacity. This includes lifesaving appliances, cranes, and lifting slings, among others.

Improperly applied swaged fittings could result in unintentional damage to the wire rope, resulting in failure of the termination. Different types of fittings/end terminations might decrease the safe working load (SWL) of the wire rope. For example, a swaged sleeve in a common turnback eye results in a 90% or better efficiency of the termination (i.e. 10% or less reduction in the SWL of the wire rope) when properly installed in accordance with manufacturer’s recommendations.

Lessons learned

- When renewing material such as wire rope and fittings, materials should be selected to match the specifications of the original equipment manufacturer.

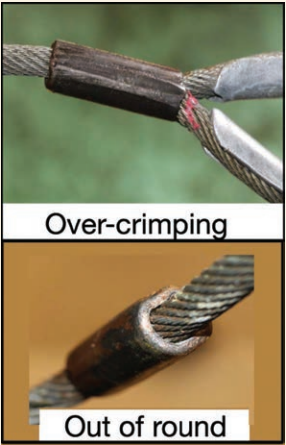

- Visually examine wire rope terminations for abnormalities that may indicate improper installation such as out-of-roundness or over-crimping.

- Ensure that the termination type does not reduce the SWL of the wire rope below the minimum safety factor for the type of service.