201626 Enclosed space fatality

Edited from official Isle of Man casualty investigation report CA118

While discharging an oil cargo from a tanker, an oil sampler (similar to that shown in the photograph) was lost to the bottom of tank 3P. It was decided that once the discharge was finished and crude oil washing completed, the sampler would be retrieved before loading the next cargo into 3P to avoid any potential damage to the ship’s equipment from the sample bucket or tape.

Once empty, the tank was ventilated. Over several days the tank atmosphere of tank 3P was measured using an explosimeter and sample hose. Although oxygen was near normal levels, HC was at 57% of LEL on day one of ventilation and 38% of LEL on day two. After discussion, it was agreed that entry into 3P tank would start the next morning (day three) if the gas levels were ‘less’.

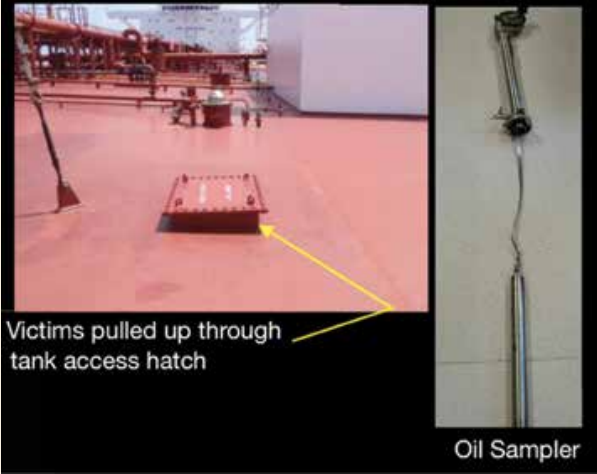

The next morning, the tank atmosphere of 3P tank was found to be 20.6% oxygen, with HC at 26% of LEL. Tank entry equipment was prepared and placed near the tank access hatch; breathing apparatus (BA) sets, emergency escape breathing devices (EEBDs), stretcher and heaving lines. The Master was shown the risk assessment and work permit for enclosed space entry and although the HC LEL was indicated at 26% he stated that the oxygen content was good. It was decided that two crew should go in, each wearing an EEBD.

Two crew members entered the cargo oil tank via the tank access hatch each with an EEBD worn over the shoulder, a torch and a personal gas meter. Several other crew members and the Master were in attendance at the tank access hatch. The lead crew member proceeded down to the first platform and checked the atmosphere across the platform with his gas meter. The second crew member then proceeded down the stairs to meet him. This was repeated for the remaining platforms until they reached the tank bottom almost 20 metres below the main deck. The lead crew member then reported feeling dizzy and heard his personal gas meter alarming. The second crew member reached the tank bottom and instantly felt the effects of the gas inhalation; he also heard his personal gas meter alarming. The lead crew member shouted and gestured to the second to wear his EEBD and leave the tank. The lead crew member felt dizzy and immediately proceeded to exit the tank. The second attempted to don his EEBD and activate it but collapsed soon afterward. Meanwhile, on deck, the Master entered the tank with an EEBD worn over his shoulder. Although another crew member warned the Master not to enter the tank the Master nonetheless proceeded into the tank. Two crew members on deck donned the BA sets already available at the entrance.

The lead crew member exited the tank and had passed the Master heading down to retrieve the second crew member, now collapsed on the tank bottom. Upon arrival at the tank bottom the Master also collapsed. Within 10 minutes, three crew members descended into the tank with BA gear in order to evacuate the two victims. The Master, secured in a Neil Robertson stretcher, was raised to the main deck by all available crew pulling the gantline to the main deck through the tank access hatch. The second victim was subsequently retrieved in the same manner.

Oxygen was administered to the victims; one victim did recover but the Master did not and was later pronounced dead.

Some of the findings of the official report were:

- Normally, inert gas is introduced into the tank to drive out the hydrocarbon content (purging) to below a level out of the flammable range before replacing the inert gas with fresh air (gas freeing – ie HC to be at 2% or less). It is not known why this procedure was not carried out in this instance.

- With a HC level of 26% LEL the atmosphere was too rich to allow an explosive condition, but was also too high to support a tank entry without BA gear.

- The rescue tripod was not made ready at the tank access hatch.

Readers comment and correction: MARS 201626 – Enclosed space fatality

The first two bullet points are of concern because they mix and match the two processes of purging a tank and then gas-freeing it.

In the MARS report 201626 we can read:

-Normally, inert gas is introduced into the tank to drive out the hydrocarbon content (purging) to a level below the flammable range before replacing the inert gas with fresh air (gas-freeing – ie HC to be at 2% or less). It is not known why this procedure was not carried out in this instance.

-With a HC level of 26% LEL the atmosphere was too rich to allow an explosive condition, but was also too high to support a tank entry without BA gear.

The first bullet would read correctly if the words “by volume” were added after the 2%. (This is the purging, and 2% hydrocarbons by volume equates to 200% of the lower explosive limit (LEL). If you then start gas-freeing and introducing air from that point the mixing of air/ hydrocarbon gas is such that you will remain outside the flammable envelope and be safe from an explosion from a source of ignition.)

The second bullet point is simply incorrect as 26% LEL is in fact too lean to allow an explosive condition, not too rich’.

Editor’s note: We are indebted to the reader for these corrections. The errors appear to have been also committed in the official published report.

Readers comment and correction: MARS 201626

A vessel’s Master wrote to inform us of some errors that had been made with respect to MARS 201626, errors that we unfortunately reproduced from the official report, and that other readers have also rightly pointed out. The reader also mentions some interesting additional ‘lessons learned’:

- A check of the atmosphere for toxic gases such as H2 S and/or benzene is recommended.

- The use of breathing apparatus (BA) sets when entering a tank where the atmosphere is known to be unsafe should be permitted only in exceptional circumstances when no other practicable, safe alternative exists.

- In accordance with the International Safety Guide for Oil Tankers and Terminal (ISGOTT), in such exceptional cases the Master should issue a statement stating that there is no practicable alternative to the proposed method of entry and that such entry is essential for the safe operation of the ship.