201119 Damage to bridge equipment due to water ingress

Several of our vessels have reported breakdown of, and damage to, navigation and communication equipment located on the navigating bridge/wheelhouse. This has been the result of water ingress through radar antennas/waveguides and cable penetrations on compass deck (monkey island) or the base of the main or radar mast.

If this results in irreparable damage to vital equipment required for communication or safe navigation, the ship can potentially become unseaworthy, with all the consequent ramifications. Further, it may entail replacement of damaged equipment on an emergency basis, which will result in off-hire time for the vessel as well as the high cost of sourcing new equipment at short notice.

In our fleet, we now require electrical officers (E/O) to examine carefully all radar antennas, cable penetrations and junction boxes on the compass deck and masts once a month and ensure watertightness as part of the planned maintenance system (PMS) on board. In addition, the E/O is required to monitor closely any repair or retrofitting involving such penetrations, to ensure that watertight integrity is maintained at all times.

Editor's note: Experience has shown that leaks through deck plating and penetration can occur even on new ships, but due to progressive corrosion and wastage this problem can become serious on older ones. Temporary repairs at sea must be carried out carefully with the full concurrence of shore management and permanent repairs effected at the earliest opportunity under class supervision/approval. Apart from malfunction/loss of vital navigation and communication equipment, such water ingress can pose a serious electrocution and fire hazard. Under some conditions, damp and condensation in the spaces inside panelling containing electrical junction/distribution boxes can also cause malfunction in critical equipment and control circuits.

An inexplicable drop in radar performance can often be traced to water in the waveguide. If the waveguide is warm to touch soon after power is turned off, it is very likely that water has entered the system. This water must be carefully drained by following the maker's service manual (usually by opening the drain provided or the first waveguide section below the wheelhouse deckhead) and a follow-up check by the maker's technician should be arranged at the next suitable port.

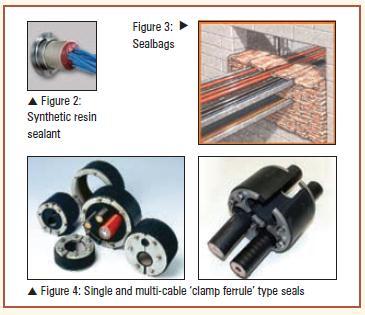

Traditionally, cable penetrations used a cement-like mixture to maintain watertightness, but these are prone to cracking. Nowadays, a variety of synthetic resins, bagged materials and 'clamp ferrule' type seals (pictured below) are available as alternatives, subject to flag state/classification society approval.